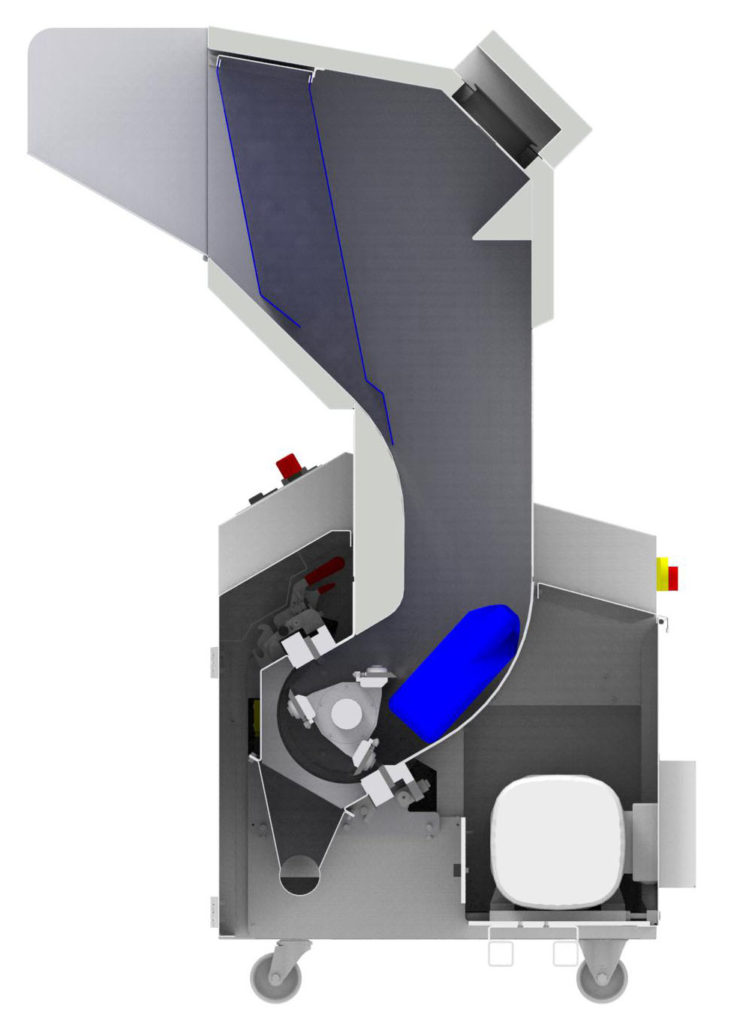

For grinding voluminous scrap or faulty parts from blow mould production, we offer tailor-made central granulators. Two technical features in particular ensure the high efficiency of the size reduction process in all these granulators: The Getecha segment rotor with its staggered rows of blades and the supertangential cutting chamber inlet, which considerably simplifies and accelerates the feeding and grabbing of voluminous plastic parts.

- grabbing of voluminous parts by means of supertangential cutting chamber or push-in device in the hopper

- cooling of material by water cooled cutting chamber, feeding of cold air into the granulator, open rotor geometry for optimum air flow through the granulator

- transport of regrind by blower provides additional cooling

Central granulators

With the granulators of the following series we solve your grinding tasks in the blow moulding industry:

| Model | Rotor cutting diameter [mm] | Cutting width [mm] |

|---|---|---|

| RS 2400-B | 240 | 200 – 900 |

| RS 30000-B | 300 | 400 – 1.500 |

| RS 38000 | 380 | 600 – 1.500 |

| RS 45000 | 450 | 600 – 1.500 |

| RS 6000 | 600 | 600 – 1.800 |

We do not only take care of the grinding, but also design and deliver a complete solution from conveying the parts to the handling of the regrind.