From the design phase to commissioning, we are a competent and reliable partner for your automation projects.

Based on our many years of experience, we offer you tailor-made solutions for your production: from simple devices to self-sufficient production cells.

Automation of your granulation processes

For your granulation and recycling requirements, we offer solutions that start with simple tilting, dosing and feeding units and include fully automated granulation systems. The solutions are optimized for

- effortless mode of operation

- minimal staff requirements and

- high energy efficiency.

The picture gallery shows only some of our realized projects. Describe us your application needs!

1/6 Feeding of loose material

The tilting devices dose the material onto the belt conveyor. Different tilting programms can be selected. The process is monitored and controlled depening on the power consumption and the volume of feeding.

2/6 Feeding of film rolls

Up to 3 film rolls can be fed into the granulator at the same time. The end of film is detected and the adhesive strips can be removed.

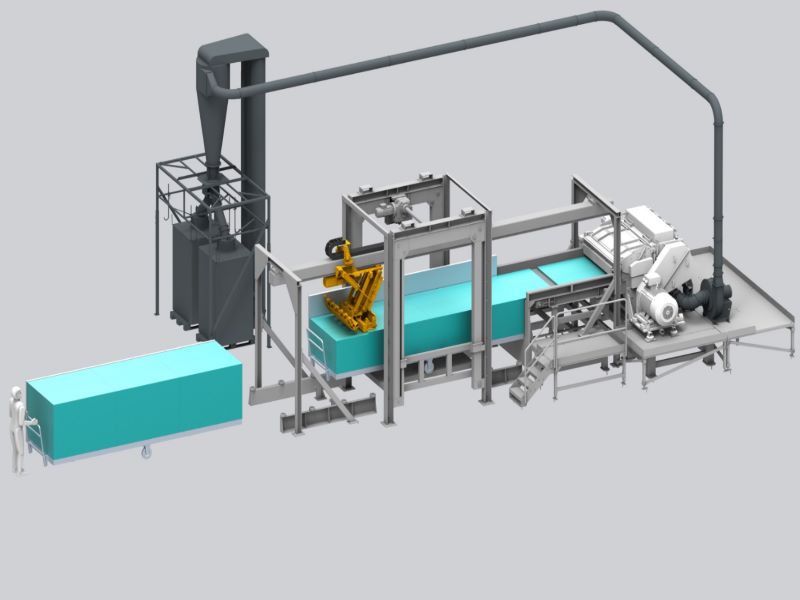

3/6 Feeding – preparation – buffering

automatic feeding via a bunker with vibratory discharge and belt conveyor; discharge of metal contamination; granulation and dedusting; buffering of the material in four regerind containers with level monitoring

4/6 Discharge of metal contamination

– by overband magnet with lateral discharge

– by head roller in belt conveyor

– by doube layer metal detector

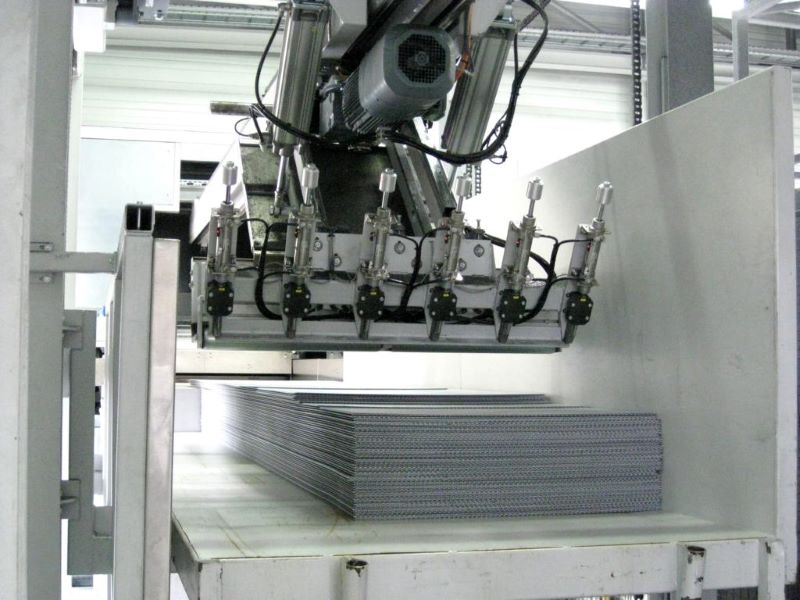

5/6 Automatic granulation of sheets

automatic transfer of sheets into a wide granulator

6/6 Gripper system for sheets

Our gripper systems can either feed the material by pushing or transfer it to the granulator by dragging.