Both at the outlet of a blowing machine and after a filling line, the controlled screwing of a cap onto a jerry can can be required. The challenge is to screw the cap on in a special way:

After a filling machine with a specified torque to guarantee tightness,

or

after a blowing machine to a specified position before the detent ring engages.

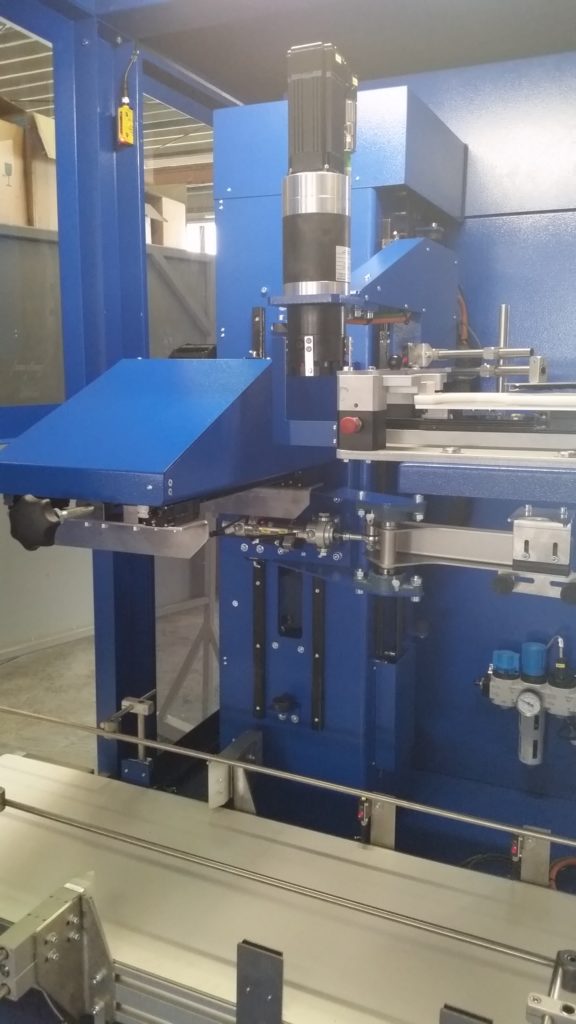

The screwing system is therefore equipped with a servo axis, which is both torque and position controlled and thus covers both application uses.

Advantages

- automatic screwing with a programmable torque up to 30 Nm

- automatic screwing to a programmable position before overwinding the detent ring

- automatic processing for different jerry can heights

- one screwing system is able to operate with several production lines

- archive function for each cycle for tracking

Installation

- cell as welded frame

- sorting of caps by water fall separator or vibration conveyor pot

- motor axix: height setting clamping, height setting screw head, screw head