Due to the large forces used in hollow self-pierce riveting, the use of hollow self-pierce riveting tongs at manual work places is only possible under increased safety requirements. The risk of sudden movements of the component and thus possible injury to the operator must be taken into account.

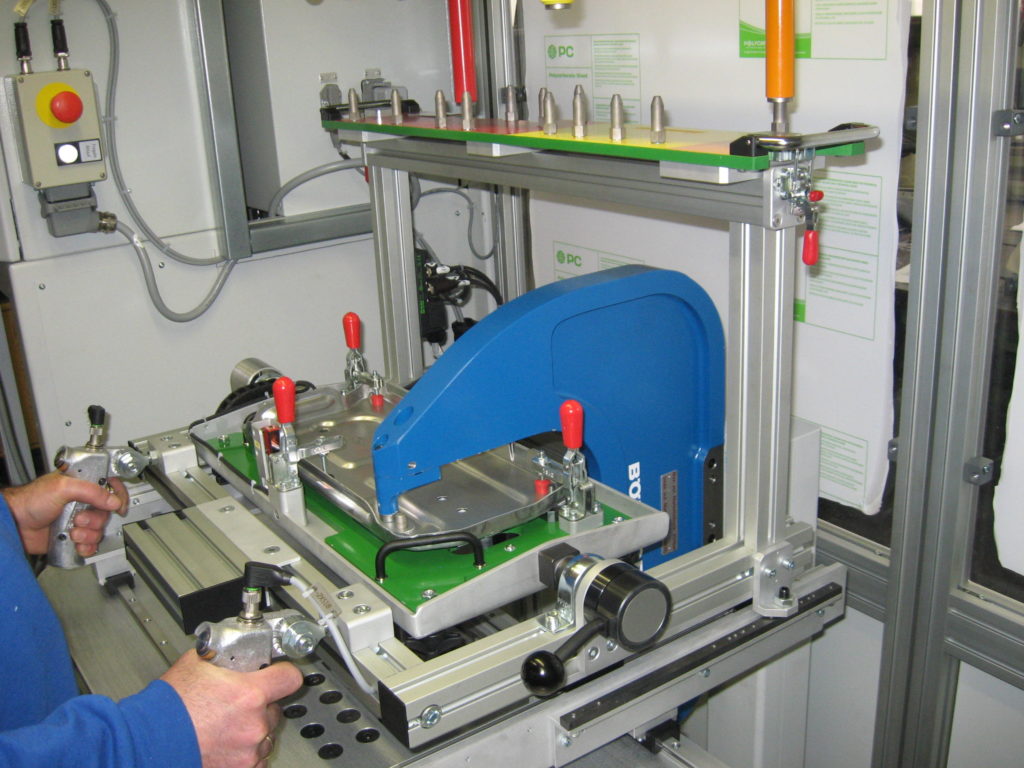

The implemented manual work station avoids direct contact of the operator with the component. It is fixed in a weight compensated device and manually guided from punching point to punching point. Change parts for different products, combined with a recipe preselection at the control unit, guarantee short product change times. In addition, each punching position is specified via an easy-to-change mask, and even different punching parameters for the individual points are possible. Finally, the number of triggers is monitored to further reduce the possibility of operating errors.

Advantages:

- safety fixing of all to be joined components, thus no misalignments

- no retroactive affects of process forces onto the operator

- weight compensated guiding of the component from punching point to punching point

- exact position of the component to the riveting tongs

- monitoring of the number of the punching points

- automatically choice of punching parameters

- short conversion times to different products

Installation:

- welded base modul

- fixed hollow punch-rivet tongs

- operator guided, weight compensated part pick-up with three movement directions and two-hand activation

- mask with pins for positioning