Large-volume parts from the injection moulding shop should be ground centrally. The larges parts are bumpers with the dimensions 1.800 mm x 800 mm, diagonal 2.000 mm and a weight of 5 kg.

The most parts are made of PP. The customer’s request was a granulator for PP and and additional one for the other materials to minimize cleaning times. The required throughput was 650 kg/hr at a regrind size of 5 – 6 mm.

Installation:

Getecha delivered the following equipment:

- angled belt conveyor with a rising part and a horizontal belt into the granulators hopper

- double-layer metal detectors

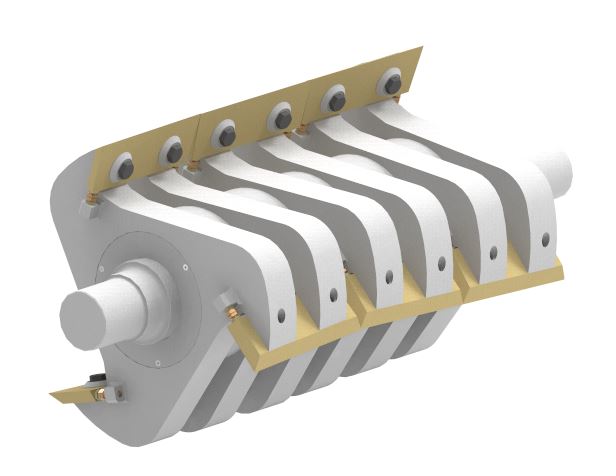

- two granulators RS 6009 with a cutting diameter of 600 mm and a inlet width of 900 mm

- The open 3-blade granulator reliabely grabs the large-volume parts and ensures an efficient granulation.

- The regrind is transported to an air classifier and dedusted. The air classifier is equipped with frequency converter, so that the optimal dedusting rate can be adjusted very sensitively.

- The exhaust air is transported into a self-cleaning filter.

- The complete system is completely grounded to minimize static charge.

Getecha delivered the complete system, set it up at the customer’s premises and started it up together with the customer. The operating and maintenance personnel received extensive training.