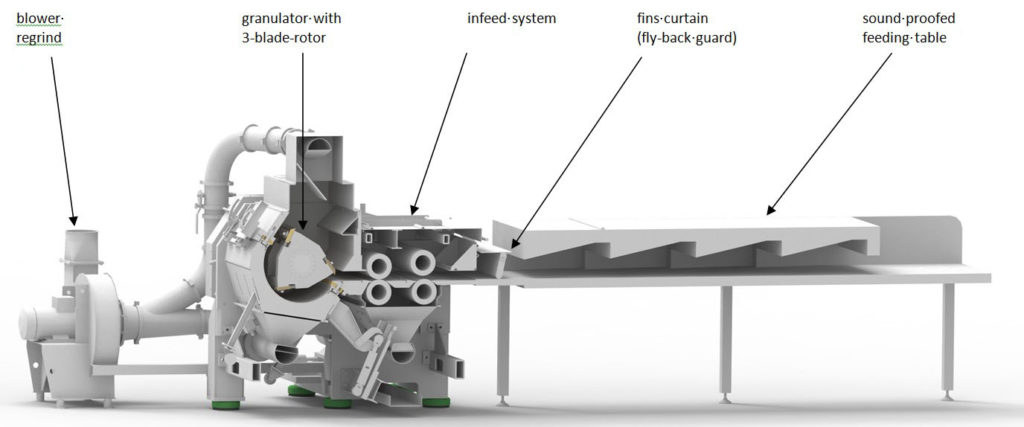

Definition of project:

Space-saving granulation of flat plastic parts, ergonomic feeding of parts

Realized projects: twin-wall sheet, foamed sheets up to 200 mm thickness, solid sheet

Mode of operation:

The material is placed on the sound-proofed feed table and pushed towards the infeed rollers. The infeed rollers are hydraulically supported and open smoothly when material is pushed in. The speed of the infeed rollers can be varied via a frequency converter. After gripping the sheet, the infeed automatically pulls in the material. The infeed height and position of the first stationary blade is optimal for an energy-efficient cut. Monitoring the current consumption of the drive motor prevents overfeeding of the granulator.

Advantages of the horizontal feeding:

- cost-effective installation of the equipment: no expensive pit construction is necessary for a two-level feeding system

- ergonomic feeding of the material: no lifting the sheets over the head, easy feeding or automated feeding

- controlled and continuous granulation: no sudden loading of the granulator by a falling sheet as with conventional hopper feeding

- hereby energy-efficient granulation without power peaks and with low power consumption

- good regrind quality due to short cut through the material

- low noise level due to long sound-proofed feeding table

- prepared for the future through high flexibility: feeding of long sheets possible without problems!

- ergonomic maintenance due to installation at ground level