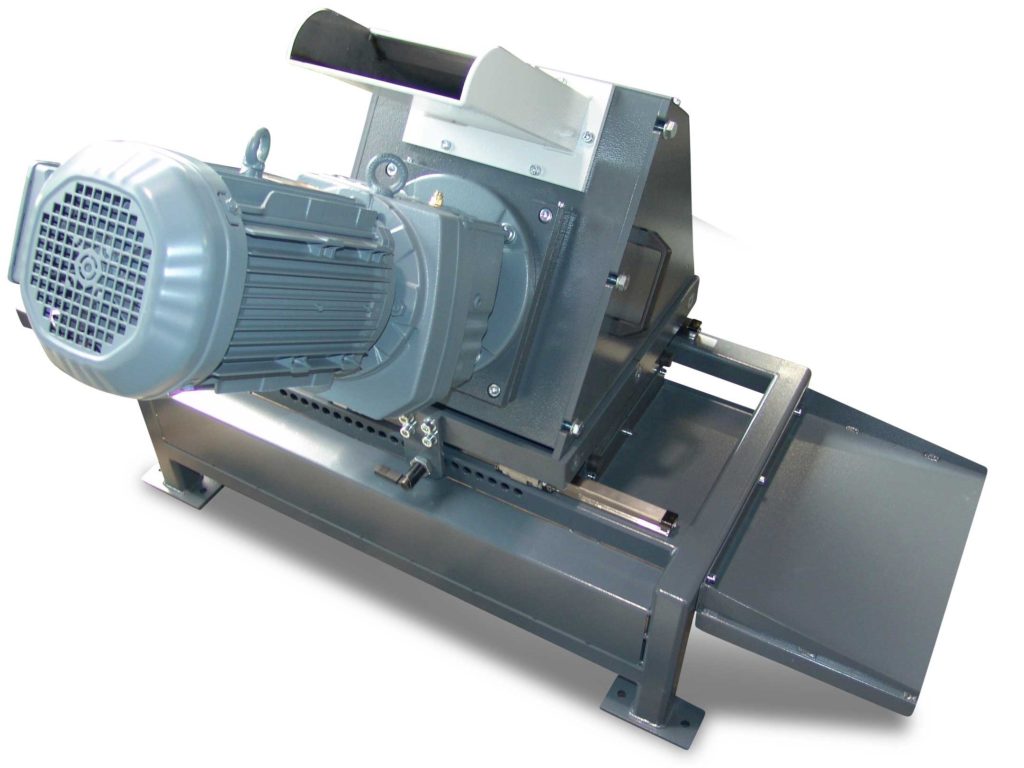

The Getecha pre-cutters cut thicker sheet edge trims directly at the extrusion line.

Typically two pre-cutters are mounted on an adjustment unit underneath the line. One cutter is used per edge strim. The cuts of the sheet fall onto a cross conveyor belt and are transported laterally out of the line.

The adjustment unit is adapted to the respective production machine so that the entire production width can be covered.

The length of the pre-cut parts depends on the line speed of the extrusion line and the number of strokes of the pre-cutter. The number of strokes of the cutters can be adapted to the line speed by a frequency converter.

Describe us your application. We will pleased to advise you.

For special applications we will test your material in our technical centre.

Technical specifications

| Model | GH 200 | GH 300 |

|---|---|---|

| Cutting width [mm] | 200 | 300 |

| Inlet opening [mm] | 200 x 20 | 300 x 20 |

| Motor power [kW] | 2,2 | 3 |

| No. of strokes [stroke/min] | 60 | 34 |