The series RS 2400 has a cutting circle of 240 mm.

The RS 2400 is built in cutting widths of 226, 452, 678 and 904 mm.

Range of applications:

- small central granulator for injection moulding

- beside the press granulator for large sprues

- jerry cans up to 5 l

- infeed granulator for edge trims, films, skeleton film and profiles

Advantages

High efficiency

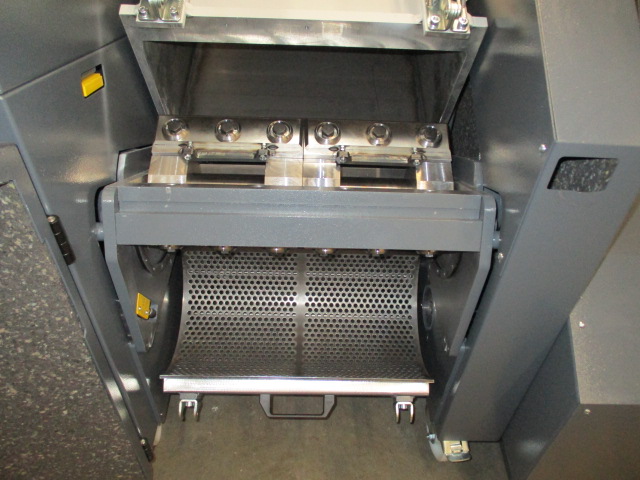

- opening of hopper and cutting chamber without tools

- screen holder removable

- low cleaning time due to smooth, all-side machined surfaces

- high energy efficiency due to cutting gemotery and EnergySave motor controller

Excellent regrind quality

- scissors cut with constand cutting circle

- stationary blade is mounted against hardened stop

- rotary blade adjustabe outside of the granulator

- blade adjustment gauge included

High realibility

- strong construction

- rotor shaft made of high quality tempering steel

- rotor segments mounted on shaft with couplings (over 20 years experience)

- solid belt pulley for a high centrifugal moment

Individual features

- water cooled cutting chamber for temperature-sensitive material

- wear protected version for filled materials

- various hopper versions

Technical specifications

| Model | RS 2402 | RS 2404 | RS 2406 | RS 2409 |

|---|---|---|---|---|

| Rotor cutting chamber [mm] | 240 | 240 | 240 | 240 |

| Cutting chamber opening [mm] | 240 x 330 | 465 x 330 | 690 x 330 | 915 x 330 |

| No. of rotary blades | 3 | 3 x 2 | 3 x 3 | 3 x 4 |

| No. of stationary blades | 2 | 2 | 2 | 2 |

| Motor power [kW] | 4,0 | 5,5 | 7,5 | 7,5 |

| Throughput* [kg/hr] | approx. 60 – 100 | approx. 100 – 160 | approx. 150 – 220 | approx. 180 – 250 |

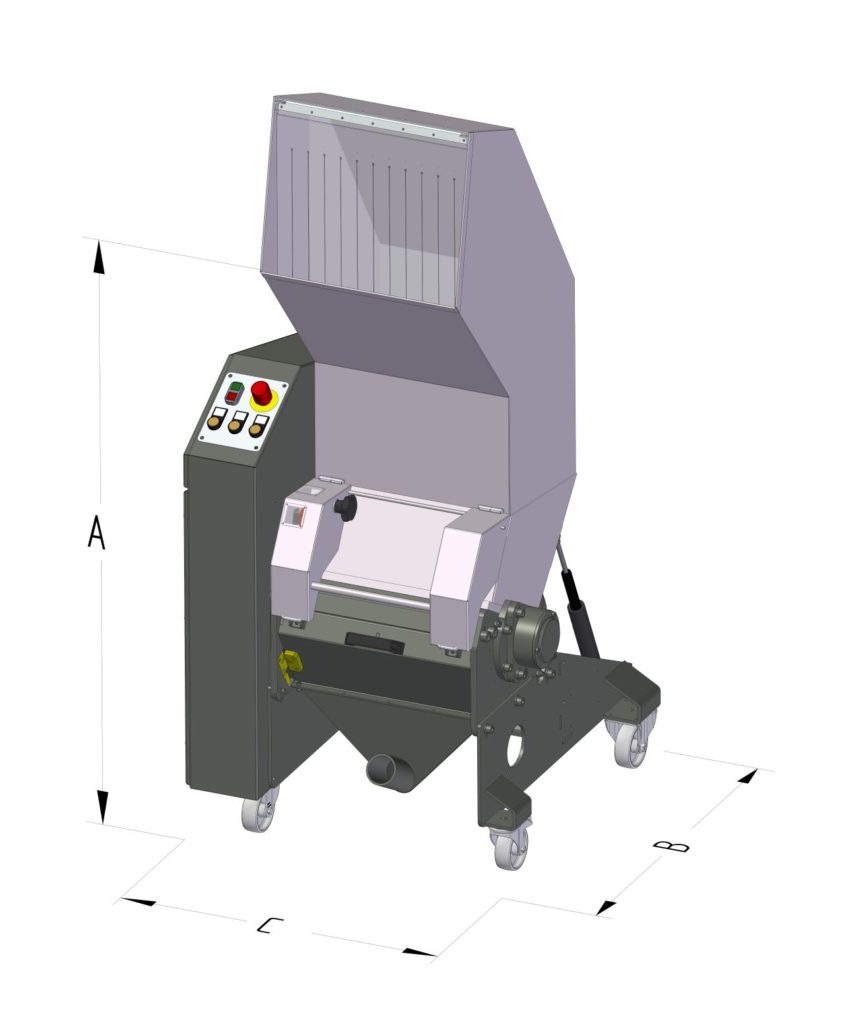

Dimensions

| Model | A | B | C |

|---|---|---|---|

| RS 2402 [mm] | 1.400 | 890 | 565 |

| RS 2404 [mm] | 1.400 | 890 | 790 |

| RS 2406 [mm] | 1.400 | 890 | 1.015 |

| RS 2409 [mm] | 1.400 | 890 | 1.240 |

Options

Various rotor versions, drives and blade qualities of the model range RS 2400 are individually designed for your application, grinding reliably, energy-saving and producing an optimum grinding material quality.

Integrated soundproof housing of the RS 2400 series reduces noise efficiently and compactly.

Suitable wear protection packages secure your investment, reduce your maintenance costs and increase your profit when grinding abrasive materials.

Water-cooled cutting chambers and cooling-air supply reduce the thermal stress on your materials, protect against plastification in the cutting chamber and enable optimum grinding even in critical applications.

Maximum energy efficiency thanks to the latest design, drive motors in the energy efficiency class up to IE 4 and the use of GETECHA EnergySave, a system that significantly reduces your power consumption under partial load.

Electrical accessories from GETECHA connect your rotary cutter RS 2400 to the peripherals, control upstream and downstream units, create safety and increase your productivity. If you need special equipment and cannot find it anywhere, please contact us.

The modular granulator platform of the GETECHA rotary cutter RS 2400 allows variations of a wide range of proven assemblies, components and functions from the entire GETECHA rotary cutter range.