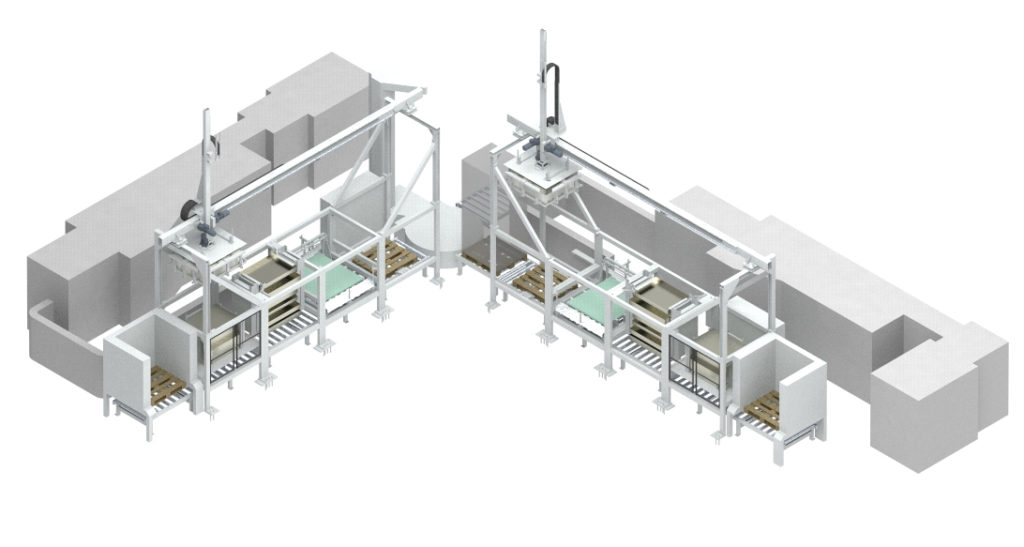

Two stretch blow molders are to stack up to 6.000 bottles per hour each with trays on pallets and pack them with stretch film ready for loading:

Size of bottles:

Carton pad:

Tray:

Size of pallets:

Height of stack:

250 – 1.000 ml

carton on pallet or as completion of the stack

insert in trays or tray as cover

Euro (1.200 x 800 mm) and industry (1.200 x 1.000 mm)

max. 2.800 mm

Features

- for all stowable and squeezable bottles

- stacking in layers with different layer patterns, also shifted

- pressureless layer formation for sophisticated bottle designs

- short conversion times through user-friendly recipe management

- no component exchange with product change

- modular system concept for flexible function expansions to meet changing requirements

- integration into the customer’s IT infrastructure by up-to-date control technology with common interfaces

- integration into customer’s peripherals, f.e. printer systems

Installation

Two packaging lines share one stretch winder

De-stacking of pallets

Carton layer

Tray magazin

Layer table

Palletizer

Buffer station

Stretcher

Handling with gripper

buffer capacity 10 – 15 pallets

suitable for carton or plastic sheet for higher hygiene requirements

paternoster construction for automatic supply, as base or cover

stop of bottles and seriation push off

providing of pallet, applying a carton, a tray or a layer of bottles

buffering of the complete pallet until it can be transferred to the subsequent system (e.g. stretcher)

The pallets with stacks of bottles are packed by a stretcher for transport.

dual-axis servo unit with combination gripper for picking up a layer of bottles or tray/carton