Many of the systems known today for the machine closing of canisters with screw caps cannot really convince in practice. Most of them lack the necessary “sensitivity” as well as accuracy and flexibility. Now, however, plant constructor Getecha has developed a new automatic screwing machine on the basis of its engineering know-how, which makes you forget all your previous problems. It can be used in two key process engineering positions: Behind the blow moulding line for loosely screwing the caps into the thread of the empty canisters or behind the filling machine for liquid-tight sealing of the full containers.

Leaking screw caps, crushed sealing rings or far too much effort for conversion when changing canister sizes – these are just some of the annoyances that make life difficult for manufacturers and users of plastic canisters. Both target groups – i.e. both blow moulding companies and liquid fillers – should therefore be delighted with the latest innovation from the Aschaffenburg-based plant manufacturer Getecha. In the last few months, the development department of the Aschaffenburg-based plant manufacturer Getecha has developed a new screw cap closure system that not only scores points for its high process reliability, but also offers unusual flexibility. The technological trademark of the fully automated system is the successful tête-à-tête of modern control and sensor technology with precisely adjustable servo drives. It gives Getecha’s system solution an unprecedented sensitivity and precision in handling screw caps and canisters. In concrete terms, this means that because the torque, tightening torque, speed of rotation and number of revolutions of the motors can be programmed, the closing process can be carried out extremely precisely, reproducibly, “force-dosed” and gently. The latter also plays a major role in maintaining the function of the PE sealing rings inside the caps. Thanks to these fine-motor qualities, the new automatic screwing machine from Getecha can be used as a handling process solution at two neuralgic points in canister handling: When the caps are placed and loosely screwed into the threaded cap of the empty canisters directly behind the blow moulding machine and when the full containers are finally sealed liquid-tight after filling.

High accuracy and process reliability

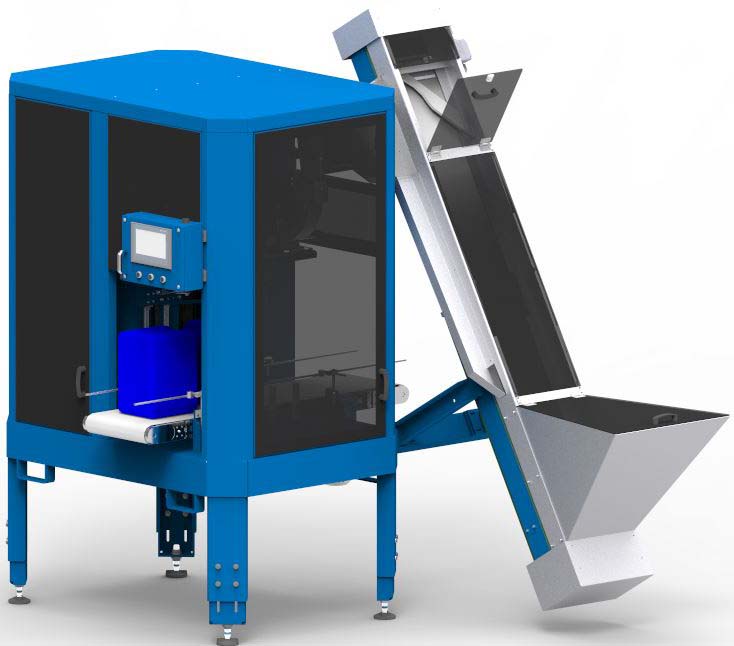

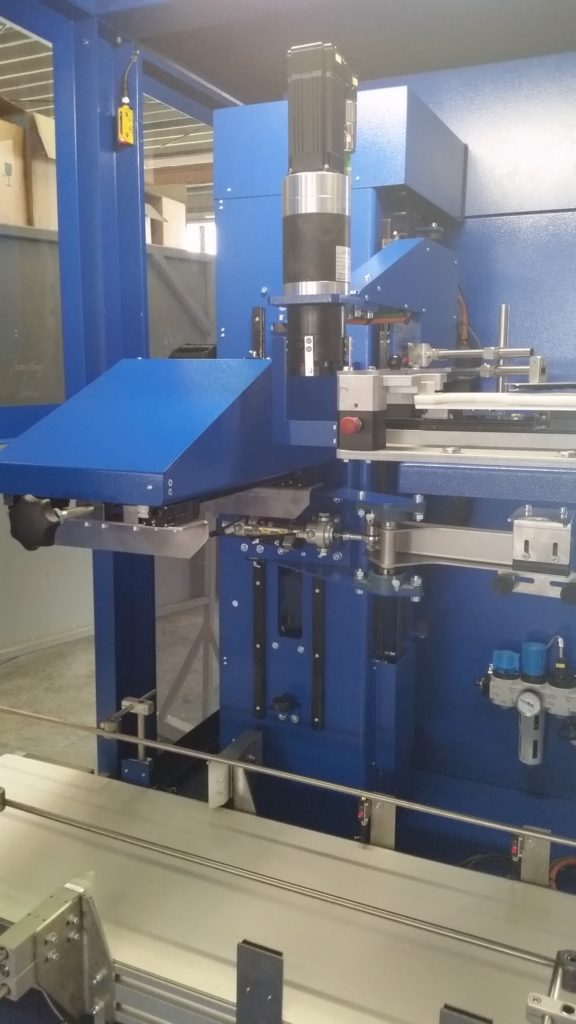

For both applications Getecha supplies the new screw cap sealing system as a fully equipped system solution that can be integrated into existing processes. While the canisters enter via a short conveyor belt, the caps are separated by an ascending and a spiral conveyor and fed to the screwing module. Each individual canister is pneumatically fixed at the defined position and shortly afterwards the screw module – moving in a linear vertical axis – approaches it from above. Screwing on is then carried out quickly, with high repeat accuracy and with due consideration for the threads and sealing rings. Depending on the size of the canisters, the entire cycle time is only 10 to 15 seconds. In addition to the dynamic torque programming of the screwdriving motors, the self-control of the system, which monitors the screwdriving process and detects defective threads, guarantees high process reliability. An interesting feature for bottling plants might be the optional integration of a leakage test.

Screw cap centering: Before the caps are supplied to the screw head, they are separated and their position is checked.

One system for several lines

However, Getecha’s engineering team has not only created an extremely reliable and precise system with the new automatic screw cap closing machines. The factors flexibility and efficiency were also high on the agenda during development. For example, it is a great advantage that the system can process different canisters without changeover and can be quickly adapted to different types of caps with minimum set-up effort. In practice, therefore, a single screw cap capping machine is capable of handling canisters with varying heights (300 – 600 mm) and widths (150 – 300 mm) coming from several blow-moulding or filling lines. Different process parameters – for example for the screwing process – can also be applied. Only the footprint of the canisters is considered a fixed size and must be identical. An average throughput of 330 containers per hour can be calculated.

With a footprint of just under 2.000 x 3.500 mm (including conveyor technology), Getecha’s new screw cap capping machine is quite compact, which benefits its easy integration into blow moulding and filling lines. The system can be connected to the customer’s host computer or network for information technology purposes – it can, for example, be synchronised with the cycle of the preceding production. Where the user archives the process data of different capping scenarios with different canisters, caps, and screwing dynamics requirements, he can decide freely – either in the control system of the machine or in his higher-level IT system. The optional installation of printers, labelling and scanners in the capping machine is part of Getecha’s range of services.

The new screw cap sealing machine from Getecha is an impressive example of engineering art made in Germany. It is likely to outperform many systems in terms of screwing precision and repeatability, as well as process reliability and flexibility. And sceptics should know that the system has already passed its baptism of fire – it has been running very successfully for several months as a two-line solution at a renowned German manufacturer of blow-moulded plastic canisters.

The automatic screwing machine can be used both for loosely screwing the caps into the threaded cap of the empty canisters directly behind the blow moulding machine and for the final closing of the full containers after filling. The picture shows the screwing unit, below it the conveyor belt on which the canisters approach.

Press release April 2018

Packaging technology / filling technology / closure technology / blow moulding / fluid technology / automation